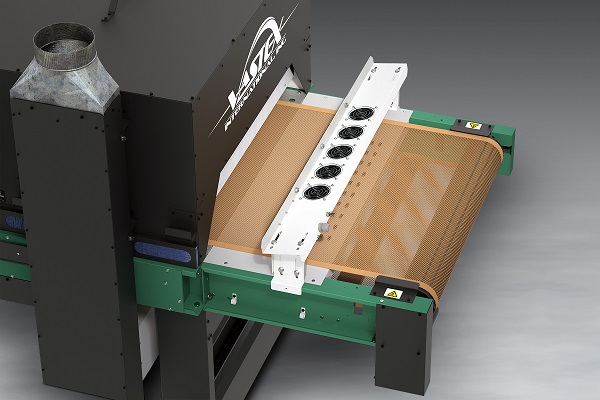

An all-new conveyor Air Bar from Vastex speeds the cooling of screen-printed and inkjet-printed garments, caps, insulated beverage holders, umbrellas and hard goods as they exit a dryer’s heating chamber, it was announced by Mark Vasilantone, president.

“The new Conveyor Air Bar is a simple way to increase productivity of any shop by rapidly cooling and hardening hot ink that is soft or tacky, making printed garments and hard goods easy to fold or package,” he says. The Air Bar houses tightly-spaced mini fans providing uniform airflow across the printed item, and is angled outward to avoid blowing cool air into the heating chamber. Adjustable in width to fit most popular conveyor dryers, it is also height adjustable to accommodate thin to bulky textiles as well as hard goods. Model CAB-30 houses five fans, and adjusts to fit any Vastex dryer having a 76 cm wide belt, or other brand dryer having an exterior conveyor width of 84 to 99 cm. A CAB-30-240 model is available for 240V systems. Model CAB-54 includes nine fans and adjusts to fit any Vastex dryer having a 137 cm wide belt, or other brand dryer having an exterior conveyor width of with a 144 to 160 cm. A CAB-54-240 model is offered for 240V systems.

#Conveyor #garments #productivity #textile #screen-printed #heating chamber #inkjet-printed